Who we are

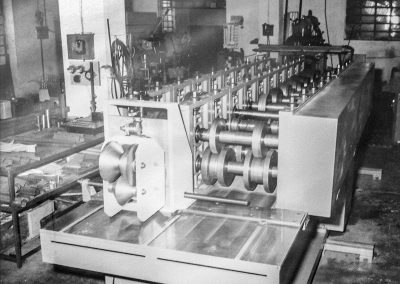

Founded in 1970, METALSISTEM commenced its activities specialising in the design and production of cold roll forming machinery.

The experience gathered, the numerous highly innovative patents resulting from research and development as well as the considerable market success of its first cold formed galvanized profile, quickly channelled METALSISTEM into the manufacturing of modular shelving systems.

Today, the METALSISTEM Group is an articulated network of companies with its head office and main production facility in Rovereto, Italy.

The Group has consolidated its position as one of the major players within in the Material Handling and Shopfitting Industry.

55+

50

Total production surface (m²)

Specialist dealers

Countries

Total production surface (m²)

Specialist dealers

Countries

Mission & Values

Mission & Values

Quality and Reliability are core METALSISTEM production values.

Production Technologies

International Patents

Product Innovation

Production Technologies

Versatility

International Patents

Prices

Product Innovation

Deliveries

We transform more

than 100˙000 tons of steel per year!

We transform more than 100˙000 tons of steel per year!

Our production facilities

Rovereto

Viale dell’Industria, 2

38068 Rovereto (TN) – Italy

Gambara

Villaggio Europa, 8

25020 Gambara (BS) – Italy

Gussago

Via Mandolossa, 100

25064 Gussago (BS) – Italy

Motta di Livenza

Via Friuli, 32

31045 Motta di Livenza (TV) – Italy

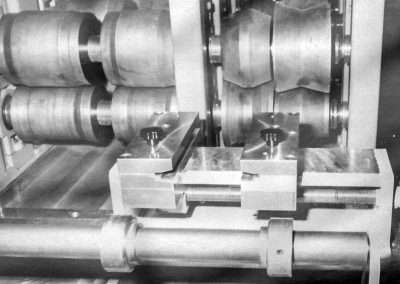

Manufacturing process

METALSISTEM’s profiles Sendzimir galvanised finish guarantees elevated resistance and durability to the product.

Coils are slit into widths by one of the most innovative and technologically advanced slitting lines available today, such to satisfy the diverse catalogue of METALSISTEM products.

The slit coils entering production are then transformed mainly using one of the following processes:

- roll forming;

- brake pressing.

The roll forming process consists of passing a continuous sheet of structural steel through a series of rollers which progressively plastically deform the material until the required form is achieved.

The brake pressing process generally uses a single action to punch out the required form from a sheet of metal through the use of a press which compresses the material against a die.

Eco Sustainability

To date, METALSISTEM has reached 75% energy self sufficiency through the almost 12’000 photovoltaic panels installed on the roof tops of its facilities.

The 38,677 m² area covered by photovoltaic panels produces 2900 Mwh per year, which contributes to the reduction of 1,622 tons of Carbon Dioxide.

In this way, METALSISTEM means to play a responsible and tangible role in the environmental safeguard and climate-change querelle.

It is in fact possible to build a successful self-sustaining business model with ZERO emissions and ZERO impact.

2'747

2'900

(MWh/year)

11'636

38'677

168

Code of Conduct

METALSISTEM is an industrial group which plays a major role in the market as well as in the overall economic environment, because of its structure, size, assets under management and connection with the territory.

Welfare of the surrounding communities, and the various institutional, economic, political, social and cultural contexts are taken into consideration when evaluating the business operations.

Sustainability report

METALSISTEM has integrated the pertinent points of the 17 “Sustainable Development Goals” into its corporate philosophy. This is an initiative established and disseminated by the UN within the 2030 Agenda for Sustainable Development with the aim of integrating sustainability drivers into daily business choices, with a view to continuous improvement.

The “Towards the 2023 Sustainability” report sets a path for economic, social and environmental sustainability that METALSISTEM has decided to undertake and in so doing, make its contribution towards a sustainable business model.

Integrated Policy

METALSISTEM’s leading market position can be maintained thanks to the long-term view and the responsible behaviour of the company’s stakeholders. Market developments are forecast with safe, reliable, competitive and sustainable solutions born by the close collaboration with clients in all industrial sectors, such to provide technologically advanced and innovative products and services.

the Origins

METALSISTEM was founded in 1970 thanks to the managerial verve and creative spirit of its founder, Antonello Briosi, role which he continues to play with tenacity and inspiration.

The company commenced its activities designing and producing roll forming machines.

The original patent is based on a modular and functional system used to create industrial storage solutions and archives able to satisfy both the most demanding industrial applications and those of the family.

The experience gathered in the production of roll forming machines, the numerous innovative patents, and the considerable market success of the first range of roll formed galvanised steel profiles quickly channelled the company in the latter of these activities supplying standards of high quality which have been recognised and certified by the most important European controlling bodies.

1970

50

Innovation

A dedicated Research and Development division has been active for years providing ongoing support to the industrial activities of the group.

By researching solutions and highly innovative products, that result from numerical analysis and experimental outcomes, METALSISTEM aims at maximising the performance levels of its products.

The advanced technological know how acquired through research and development has enabled METALSISTEM to patent its inventions and to produce industrialised products.

The use of refined calculation methods and sophisticated experimental techniques, has enabled METALSISTEM to certify the QUALITY and SAFETY of its products.

Innovation

A dedicated Research and Development division has been active for years providing ongoing support to the industrial activities of the group.

By researching solutions and highly innovative products, that result from numerical analysis and experimental outcomes, METALSISTEM aims at maximising the performance levels of its products.

The advanced technological know how acquired through research and development has enabled METALSISTEM to patent its inventions and to produce industrialised products.

The use of refined calculation methods and sophisticated experimental techniques, has enabled METALSISTEM to certify the QUALITY and SAFETY of its products.

Our business

Exclusive indoor & outdoor furnishing concepts made of stainless steel